Bottlenecks in COVID-19 vaccine production cause a stir

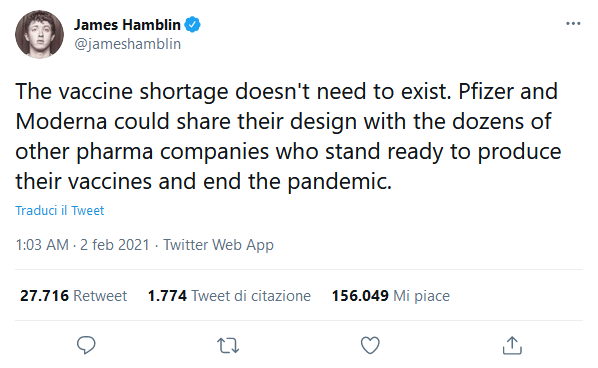

A tweet from Dr. James Hamblin sparked a discussion on whether more pharmaceutical companies should be involved in the production of anti-COVID mRNA vaccines.

Combining mRNA and lipids into lipid nanoparticles is the biggest technological hurdle in the entire Modern and Pfizer/BioNTech vaccine manufacturing process

A tweet from Dr. James Hamblin sparked discussion about whether more pharmaceutical companies should be involved in the production of anti-COVID mRNA vaccines. Derek Lowe, a medicinal chemist with expertise in preclinical molecule development, commented on the tweet from his "In The Pipeline" blog.

Made in cooperation with our partners from esanum.it

There has been a lot of discussion in recent days about the issue of the supply of anti-COVID vaccines. Many have questioned why, given the global emergency, more pharmaceutical companies have not been enlisted to produce the vaccines. A major boost to this aspect of the discussion came from a tweet by public health physician Dr. James Hamblin. "Vaccine shortages have no reason to exist. Pfizer and Moderna could share their project with dozens of other pharmaceutical companies that are ready to produce their own vaccine and end the pandemic," Dr. Hamblin wrote a few days ago.

Derek Lowe addressed the issue on his blog "In the pipeline" by concluding that there are not "dozens of other pharmaceutical companies" that "are ready" to produce these mRNA vaccines. In fact, according to Lowe, the production chain for this particular type of Pfizer/BioNTech and Moderna vaccines involves a key step that cannot be easily delegated.

mRNA vaccines are not traditional vaccines; they are the result of a new technology that has been in development for the past two decades. Lowe points out that, fortunately, many issues in these types of vaccines have been resolved recently before the pandemic broke out. As recent as five years ago, it would not have been possible to go from genetic sequencing to vaccine production in a single year.

So it's a new technology, involving techniques, tools and knowledge not readily available. Lowe examines the production steps of these new vaccines to explain what prevents "dozens of other pharmaceutical companies" from doing the same. To simplify the issue, the Modern and Pfizer/BioNTech vaccine production chain is explained:

- Produce the appropriate stretch of DNA and contain the sequence you need to have transcribed into mRNA. This is generally done using a bacterial culture.

- Produce the mRNA from the DNA template using enzymes in a bioreactor.

- Produce the lipids that you need for formulation. Some of these are fairly common (such as cholesterol), but key ones are not common at all.

- Combine mRNAs and lipids into lipid nanoparticles (LNPs). This is the biggest technological hurdle in the entire process.

- Combine the LNPs with the other components of the formulation (phosphate buffers, saline, sucrose, and so on) and fill the vials.

- Put those vials into trays, packages, boxes, crates, and load them onto trucks and airplanes.

DNA and mRNA production

DNA production is not difficult. Pfizer does it itself in St. Louis (USA), and Moderna outsources it to the Swiss company Lonza (a good deal of Lonza's work is done in Portsmouth, USA). The production of DNA plasmids on an industrial scale (i.e., a few grams) is a very elaborate procedure. However, it is not this step that is the bottleneck. If more DNA were needed, more biopharmaceutical companies could be involved and more would be produced.

The second step, transcription into mRNA, is also not limiting. Pfizer and BioNTech do it in Andover, USA, and in BioNTech facilities in Germany. They have manufacturing infrastructure in Idar-Oberstein, and last fall they purchased another facility in Marburg (Germany) that is being prepared for such manufacturing. As for Moderna, that phase is also being handled by Lonza. Certainly this is not a common industrial process, as it is only recently that companies have started to consider RNA as real pharmaceutical substances, worthy of scale production. Because of this, RNA production is certainly closer to being a limiting factor than DNA production, but according to Lowe this is nothing compared to the actual bottleneck of this production chain.

Lipid Production

Lipid production does not have to be done sequentially, as with the DNA/RNA steps. The production of the lipids needed for the vaccine formula are a completely separate manufacturing process. Pfizer and BioNTech are relying on the British company Croda, with production in Alabama (USA), for this. This is a far from trivial step, considering that some lipids must have positively charged groups, a crucial part of the formula. Producing them on a large scale is not easy, but according to Lowe, this is not the limiting factor in production anyway. If it were necessary, some other manufacturers could certainly be set up to accelerate the process.

Phase five and phase six

These are steps running at a good pace, and these are more traditional functions for a pharma company (or any manufacturing company). Pfizer is doing this in Kalamazoo, Michigan, and Puurs, Belgium. BioNTech is doing it in several locations in Germany and Switzerland, either in its own facilities or through at least two contracted firms. Moderna, meanwhile, is outsourcing this to some of the big players in the U.S. and Europe: Catalent, Rovi, and Recipharm. Everyone in this part of the manufacturing business knew for months that sooner or later the need to produce and distribute vaccines on a large scale would come, so they were prepared to increase the available production lines.

Step four, the real bottleneck

Turning a mixture of mRNA and a set of lipids into a well-defined mixture of solid nanoparticles with consistent encapsulation of the mRNA is the difficult part of the process. It appears that Moderna does this in its labs, Pfizer/BioNTech in Kalamazoo, and also in Europe. According to Lowe, both almost certainly use a purpose-built microfluidic device. Microfluidics is the science that studies the high-precision control and manipulation of geometrically constrained fluids in networks of small channels, usually less than 100 µm in diameter. This is an area of research that has been much studied in recent years.

According to Lowe, a special device has been built that has a large number of very small reaction chambers, running in parallel, that have equally small and very precisely controlled flows of mRNA and the various lipid components that go into them. It's a matter of precisely controlling the flow rates, concentrations, temperature, and probably other parameters, bearing in mind that the size of the channels and the size and shape of the mixing chambers are also critical. Lowe also argues that special purpose-specific machines were built to produce these vaccines, which other pharmaceutical companies do not have.

This process is nothing like a traditional drug manufacturing process. This, according to Derek Lowe, is the main reason why you can't just bring in those "dozens" of other companies and ask them to move their existing production to make mRNA vaccines. There are not dozens of companies making DNA templates on the scale needed. There are certainly not dozens of companies that can make enough RNA. More importantly, you can count on one hand the number of facilities that can make lipid nanoparticles. That's not to say that other machines can't be built, but, according to Lowe, Pfizer, BioNTech, Moderna (and even CureVac) have largely filled capacity for this kind of expansion as well.

The rest of the pharmaceutical industry is already mobilising. Sanofi, for example, has already announced that it will help Pfizer and BioNTech, but not until the next few months. Although Sanofi is one of the largest and most knowledgeable companies that could join in a vaccine manufacturing effort, it won't make an impact downstream of the supply chain until at least August 2021, confirming that manufacturing these vaccines is no simple matter.

That's why, according to Lowe, it's false to say that there are "dozens of companies that are ready" to produce vaccines and "end this pandemic." The companies that can do this are a few, the same ones we've been hearing about for months, and who are certainly not standing idly by.

Source:

Lowe D. Myths of Vaccine Manufacturing. In the pipeline - Science Translational Medicine. February 2, 2021